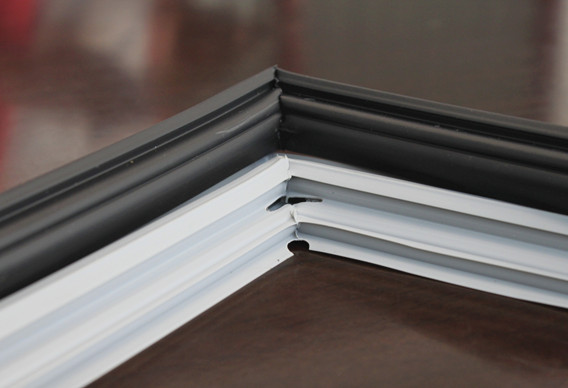

Plastic Extrusion

Plastic extrusion process:

First, plastic pellets are gravity fed from a hopper into a jacketed screw. As the screw turns about its axis, it transports, melts, and pressurizes the plastic. From there, the molten material is forced through a die to form the desired shape.

Star Seals Co has started to produce plastic extrusion profiles since 2002.

The types of thermoplastic compounds we used in making plastic extrusion:

PVC (rigid and soft), TPEs, ABS, Nylon, PE, HDPE and more.

Star Seals Co is your trust source of plastic extrusion profiles, we can provide you following service:

1. Plastic extrusion design

2. Plastic extrusion tool making

3. Plastic extrusion manufacturing, which include single and dual hardness plastic profiles.

4. Others, such as cutting, punching and drilling holes service.

Compliant:

All our plastic extrusion profiles are RoHS compliant.

For more information, please kindly download our e-catalog or send us a drawing for quotation